i previously jacked up the splitting joist by 1/8 to 1/4 inch per day. this allowed me to span from one girder to the other girder. I was able to get a 84" section of 2x8 down into the crawlspace.

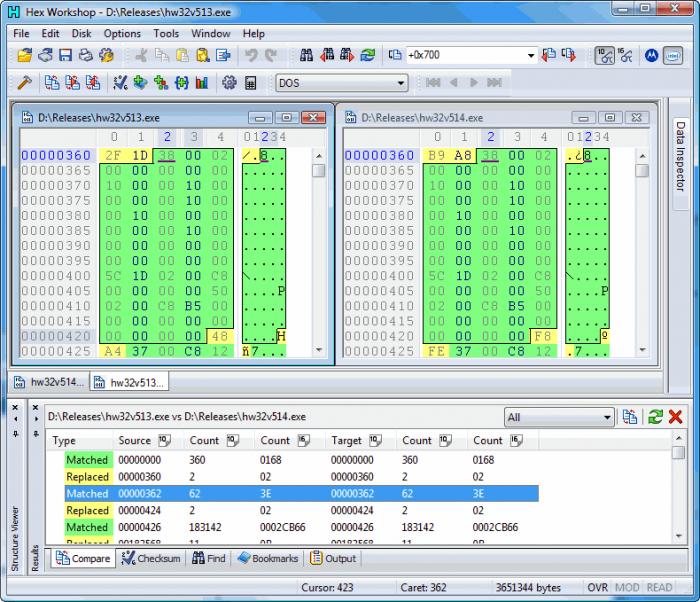

Hex workshop crack update#

Not sure if this is the correct way but wanted to give an update on what i did and maybe someone can use i what found to be helpful if they have the same situation. Continue slowly and steadily until the entire bolt has been fully extracted, ideally salvaging the threading so you want can put a new bolt in.Thanks for all the input especially since my background is not in construction. The broken bolt should soon “grab” onto the extraction bit while reverse drilling, and begin extracting. Slow and gentle is critical here: The bit is likely made of hardened steel, and if it breaks off during this process, you’ll face an even more challenging extraction. Still using a very slow reverse-drilling setting, such as 20 RPM, begin drilling into the pilot hole.

STEP 4: Reverse-drill slowly to remove a broken bolt. Exchange the first bit for the extraction bit in your drill, insert it in the pilot hole, and very gently tap your drill and the bit snuggly into place with a hammer. The extraction bit is also a left-handed drill bit (but with a different purpose), so you’ll continue using the reverse drilling setting. Check your extraction kit’s table for the right size bit for the bolt size. STEP 3: Switch to an extraction bit.įor a stubbornly entrenched bolt, you’ll need an extraction bit. If the bolt hasn’t loosened at all, proceed to Step 3 for extraction. Remember, “righty-tighty, lefty-loosey”-turn the bolt left (counter-clockwise) to remove it. Hopefully, reverse-drilling your pilot hole will loosen the bolt enough to let you use vise grip pliers to remove the bolt. Now, place the drill bit on the punch mark you made and, holding the drill securely, slowly reverse-drill a small pilot hole in the bolt, about ¼-inch deep. The torque of drilling in reverse (i.e., counter-clockwise) will prevent you from further tightening the threads on the bolt. Set your drill on reverse and as slow a speed as possible (ideally, 20 RPM), and insert the left-handed drill bit.

Hex workshop crack pro#

Pro Tip: If you’re picking up a kit for the job, invest in quality the last thing you need is a cheap bit breaking during this process. This provides a better bite when you use your drill in reverse to remove a fastener.

STEP 2: Slowly, use a left-handed drill bit to create a pilot hole.Ĭheck the table on your extraction kit to select the proper-sized left-handed drill bit (also called a “reverse drill bit”) to make a pilot hole in this broken bolt. Unlike traditional drill bits, which are considered right-handed and threaded in a clockwise direction, left-handed bits are designed with a counter-clockwise thread. Furthermore, if the threading on the bolt hole is damaged, you may be unable to use a new bolt once the old one is extracted. If the threads on either the bolt or the bolt hole are damaged, it may make bolt removal impossible. A precise pilot hole is critical to help you to avoid damaging the threads of the broken bolt when you extract it. Hit it squarely with the hammer to create a starting point for drilling a pilot hole. Place the center punch as close to the middle of the broken bolt as possible.

Photo: STEP 1: Hammer the center punch in the middle of your broken bolt.

0 kommentar(er)

0 kommentar(er)